Leather, one of humanity’s earliest and most versatile materials, has been used for various purposes for thousands of years. Whether it be in the fashion industry, automotive sector, or upholstery market, leather’s unique qualities make it highly sought-after. However, the journey of leather begins with raw materials sourced from various animal hides and skins. This summary provides an overview of leather raw materials, including their types, sources, and the processing methods used to transform them into the finished, high-quality leather products we see on the market today. Types of Leather Raw Materials: 1. Cowhide: Cowhide is the most commonly used leather raw material. It is durable, strong, and resistant, making it suitable for a wide range of products such as furniture, shoes, belts, and accessories. 2. Sheepskin: Sheepskin is known for its softness and flexibility. This material is commonly used in the production of apparel, footwear, and rugs. Sheepskin leather is highly valued for its warmth and comfort. 3. Goat and Kid Leather: Goat and kid leather are lightweight and supple, offering excellent breathability and durability. They are often employed in the creation of gloves, fine leather products, and garments. 4. Pigskin: Pigskin leather is known for its grainy texture and pliability. It is commonly used in the manufacturing of gloves, footwear, and garments. 5. Exotic Leather: Exotic leathers, such as crocodile, snake, lizard, and ostrich, are highly sought-after due to their unique patterns and textures. These materials are used in the production of luxury items, including handbags, belts, and shoes. Sources of Leather Raw Materials: 1. Slaughterhouses and Abattoirs: The majority of leather raw materials are sourced from animals raised for meat consumption. Slaughterhouses and abattoirs provide a significant supply of hides and skins for the leather industry. 2. Farms: Some leather comes from specialized farms where animals, such as cows, goats, and ostriches, are raised primarily for their hides and skins. These farms focus on maintaining the quality and health of the animals to ensure premium leather production. 3. Hunting: Exotic leathers often come from hunting activities. Animals like crocodiles, snakes, and lizards are carefully sourced and harvested under specific regulations to maintain population balance and minimize environmental impact. 4. Recycling: Leather can also be obtained through recycling techniques, where discarded leather products or offcuts are collected and processed. This helps reduce waste and ensures sustainable practices within the leather industry. Processing Methods: 1. Curing and Preservation: Immediately after an animal is slaughtered, the hide or skin is removed and processed to prevent decomposition.

leather

Preservation methods include salting, pickling, and chilling. This step is crucial to maintain the quality and integrity of the raw material. 2. Soaking and Fleshing: The preserved hides are soaked to remove dirt, blood, and excess salt. The fleshing process involves removing any remaining fats, muscles, and connective tissues from the hide. 3. Liming: Liming is a chemical process that removes hair and epidermis from the hide, making it suitable for further processing. This step is achieved by soaking the hides in lime or calcium hydroxide solutions. 4. Splitting: Depending on the desired thickness and quality, hides can be split into multiple layers. The top layer, known as the grain split, is used to produce high-quality leather, while the lower layers, called suede, are often used for less expensive products. 5. Tanning: Tanning is the most critical step in the leather production process as it transforms the raw animal hide into a stable, resistant material. Tanning can be done using either vegetable tanning or chrome tanning methods. Vegetable tanning utilizes natural tannins from bark and plants, whereas chrome tanning employs chromium salts. Both methods have their advantages and are suitable for different applications. 6. Finishing: After tanning, the leather may undergo further processing, including dyeing, brushing, embossing, or coating. These finishing techniques enhance the appearance, color, and texture of the leather, making it suitable for specific products. Conclusion: Leather raw materials come from various animal hides and skins, each possessing unique characteristics that determine their suitability for different applications. Through a careful and extensive manufacturing process that includes curing, soaking, liming, splitting, and tanning, these raw materials are transformed into the desired leather products. Understanding the types and sources of leather raw materials, as well as the processing methods involved, is essential for crafting high-quality and sustainable leather goods that cater to diverse consumer demands. Types of Leather Raw Materials 1. Cowhide: Cowhide is the most widely used leather raw material due to its durability and versatility. It is commonly used in the production of furniture, shoes, belts, jackets, and accessories. Cowhide has a natural texture and is available in various grains, making it suitable for both high-end and more affordable products. 2. Sheepskin: Sheepskin leather is renowned for its softness and luxurious feel. It is commonly used in the manufacturing of apparel, footwear, and home decor items such as rugs and cushions. Sheepskin leather provides excellent insulation, making it suitable for cold weather garments and accessories. 3. Goat and Kid Leather: Goat and kid leather are known for their lightweight and supple nature. They offer excellent breathability and flexibility, making them ideal for the production of gloves, fine leather products, and garments. This type of leather is highly sought-after in the fashion industry for its smooth texture and durability.

Preservation methods include salting, pickling, and chilling. This step is crucial to maintain the quality and integrity of the raw material. 2. Soaking and Fleshing: The preserved hides are soaked to remove dirt, blood, and excess salt. The fleshing process involves removing any remaining fats, muscles, and connective tissues from the hide. 3. Liming: Liming is a chemical process that removes hair and epidermis from the hide, making it suitable for further processing. This step is achieved by soaking the hides in lime or calcium hydroxide solutions. 4. Splitting: Depending on the desired thickness and quality, hides can be split into multiple layers. The top layer, known as the grain split, is used to produce high-quality leather, while the lower layers, called suede, are often used for less expensive products. 5. Tanning: Tanning is the most critical step in the leather production process as it transforms the raw animal hide into a stable, resistant material. Tanning can be done using either vegetable tanning or chrome tanning methods. Vegetable tanning utilizes natural tannins from bark and plants, whereas chrome tanning employs chromium salts. Both methods have their advantages and are suitable for different applications. 6. Finishing: After tanning, the leather may undergo further processing, including dyeing, brushing, embossing, or coating. These finishing techniques enhance the appearance, color, and texture of the leather, making it suitable for specific products. Conclusion: Leather raw materials come from various animal hides and skins, each possessing unique characteristics that determine their suitability for different applications. Through a careful and extensive manufacturing process that includes curing, soaking, liming, splitting, and tanning, these raw materials are transformed into the desired leather products. Understanding the types and sources of leather raw materials, as well as the processing methods involved, is essential for crafting high-quality and sustainable leather goods that cater to diverse consumer demands. Types of Leather Raw Materials 1. Cowhide: Cowhide is the most widely used leather raw material due to its durability and versatility. It is commonly used in the production of furniture, shoes, belts, jackets, and accessories. Cowhide has a natural texture and is available in various grains, making it suitable for both high-end and more affordable products. 2. Sheepskin: Sheepskin leather is renowned for its softness and luxurious feel. It is commonly used in the manufacturing of apparel, footwear, and home decor items such as rugs and cushions. Sheepskin leather provides excellent insulation, making it suitable for cold weather garments and accessories. 3. Goat and Kid Leather: Goat and kid leather are known for their lightweight and supple nature. They offer excellent breathability and flexibility, making them ideal for the production of gloves, fine leather products, and garments. This type of leather is highly sought-after in the fashion industry for its smooth texture and durability.

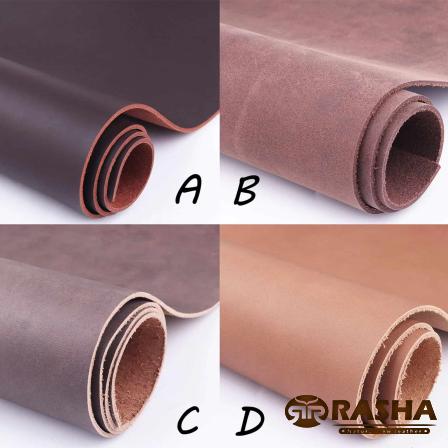

Specifications of leather

4. Pigskin: Pigskin leather is characterized by its grainy texture and pliability. It is often used in the manufacturing of gloves, footwear, and garments. Pigskin leather is known for its water resistance and ability to withstand wear and tear, making it a popular choice for athletic and outdoor products. 5. Exotic Leather: Exotic leathers such as crocodile, snake, lizard, and ostrich are highly prized for their unique patterns, textures, and luxurious appeal. These materials are commonly used in the production of high-end fashion accessories and luxury items like handbags, belts, shoes, and wallets. Exotic leathers require specialized processing techniques due to their unique characteristics. Sources of Leather Raw Materials: 1. Slaughterhouses and Abattoirs: The majority of leather raw materials are obtained from animals raised for meat consumption. Slaughterhouses and abattoirs provide a significant supply of hides and skins for the leather industry. These facilities ensure that the hides and skins are carefully processed to preserve their quality. 2. Farms: Some leather comes from specialized farms where animals like cows, goats, and ostriches are raised primarily for their hides and skins. These farms focus on maintaining the health and well-being of the animals while ensuring the production of premium-quality leather. 3. Hunting: Exotic leathers often come from hunting activities, where specific regulations are followed to ensure sustainability and minimize environmental impact. Animals such as crocodiles, snakes, and lizards are carefully sourced and harvested for their hides and skins. 4. Recycling: Leather can also be obtained through recycling techniques, where discarded leather products or offcuts are collected and processed. This not only helps in reducing waste but also promotes environmentally-friendly practices within the leather industry. Processing Methods: 1. Curing and Preservation: After the animal is slaughtered, the hide or skin is removed and processed to prevent decomposition. Preservation methods include salting, pickling, and chilling. This step is crucial to ensure that the raw material remains in optimal condition for further processing. 2. Soaking and Fleshing: The preserved hides are soaked in water to rehydrate them and remove any dirt, blood, and excess salt. This is followed by the fleshing process, where any remaining fats, muscles, and connective tissues are removed from the hide. This step prepares the hide for the next stage of processing. 3. Liming: Liming is a chemical process that removes hair and the outer epidermis from the hide, making it suitable for further processing. The hide is soaked in a lime or calcium hydroxide solution to loosen the hair and epidermis, which are then easily scraped off the surface. 4. Splitting: Depending on the desired thickness and quality, hides can be split into multiple layers. The top layer, known as the grain split, is used to produce high-quality leather with a smooth surface. The lower layers, known as suede or split leather, have a rougher texture and are often used for less expensive products.

4. Pigskin: Pigskin leather is characterized by its grainy texture and pliability. It is often used in the manufacturing of gloves, footwear, and garments. Pigskin leather is known for its water resistance and ability to withstand wear and tear, making it a popular choice for athletic and outdoor products. 5. Exotic Leather: Exotic leathers such as crocodile, snake, lizard, and ostrich are highly prized for their unique patterns, textures, and luxurious appeal. These materials are commonly used in the production of high-end fashion accessories and luxury items like handbags, belts, shoes, and wallets. Exotic leathers require specialized processing techniques due to their unique characteristics. Sources of Leather Raw Materials: 1. Slaughterhouses and Abattoirs: The majority of leather raw materials are obtained from animals raised for meat consumption. Slaughterhouses and abattoirs provide a significant supply of hides and skins for the leather industry. These facilities ensure that the hides and skins are carefully processed to preserve their quality. 2. Farms: Some leather comes from specialized farms where animals like cows, goats, and ostriches are raised primarily for their hides and skins. These farms focus on maintaining the health and well-being of the animals while ensuring the production of premium-quality leather. 3. Hunting: Exotic leathers often come from hunting activities, where specific regulations are followed to ensure sustainability and minimize environmental impact. Animals such as crocodiles, snakes, and lizards are carefully sourced and harvested for their hides and skins. 4. Recycling: Leather can also be obtained through recycling techniques, where discarded leather products or offcuts are collected and processed. This not only helps in reducing waste but also promotes environmentally-friendly practices within the leather industry. Processing Methods: 1. Curing and Preservation: After the animal is slaughtered, the hide or skin is removed and processed to prevent decomposition. Preservation methods include salting, pickling, and chilling. This step is crucial to ensure that the raw material remains in optimal condition for further processing. 2. Soaking and Fleshing: The preserved hides are soaked in water to rehydrate them and remove any dirt, blood, and excess salt. This is followed by the fleshing process, where any remaining fats, muscles, and connective tissues are removed from the hide. This step prepares the hide for the next stage of processing. 3. Liming: Liming is a chemical process that removes hair and the outer epidermis from the hide, making it suitable for further processing. The hide is soaked in a lime or calcium hydroxide solution to loosen the hair and epidermis, which are then easily scraped off the surface. 4. Splitting: Depending on the desired thickness and quality, hides can be split into multiple layers. The top layer, known as the grain split, is used to produce high-quality leather with a smooth surface. The lower layers, known as suede or split leather, have a rougher texture and are often used for less expensive products.

buy leather

5. Tanning: Tanning is a critical step in the leather production process as it transforms the raw animal hides into a stable material that is resistant to decay and breakdown. The tanning process can be done using either vegetable tanning or chrome tanning methods. 6. Vegetable Tanning: Vegetable tanning involves using natural tannins derived from plant extracts, such as bark or leaves, to treat the hides. This method is known for producing high-quality, environmentally-friendly leather with a natural appearance and a characteristic aroma. Vegetable-tanned leather is used in luxury goods and high-end products. 7. Chrome Tanning: Chrome tanning, also known as mineral tanning, relies on chromium salts to treat the hides. This process is faster and more economical compared to vegetable tanning, and it produces a softer, more supple leather with a wide range of colors. Chrome-tanned leather is commonly used in the production of footwear, bags, and upholstery. 8. Finishing: After tanning, the leather may undergo additional processing known as finishing. This includes dyeing, brushing, embossing, or coating the leather to enhance its appearance, color, and texture. Finishing techniques help create a variety of finishes, from smooth and glossy to textured or matte, depending on the desired final product. Conclusion: Leather raw materials are derived from various animal hides and skins, each with its unique characteristics and suitability for different applications. The leather production process involves careful sourcing, processing, and tanning of the raw materials to achieve high-quality, durable, and aesthetically pleasing leather products. Understanding the types of leather raw materials, their sources, and the various processing methods employed is crucial for businesses operating in the leather industry. By utilizing sustainable sourcing practices and adopting efficient processing techniques, businesses can produce environmentally-friendly and ethically sourced leather goods that meet the demands of consumers worldwide.

5. Tanning: Tanning is a critical step in the leather production process as it transforms the raw animal hides into a stable material that is resistant to decay and breakdown. The tanning process can be done using either vegetable tanning or chrome tanning methods. 6. Vegetable Tanning: Vegetable tanning involves using natural tannins derived from plant extracts, such as bark or leaves, to treat the hides. This method is known for producing high-quality, environmentally-friendly leather with a natural appearance and a characteristic aroma. Vegetable-tanned leather is used in luxury goods and high-end products. 7. Chrome Tanning: Chrome tanning, also known as mineral tanning, relies on chromium salts to treat the hides. This process is faster and more economical compared to vegetable tanning, and it produces a softer, more supple leather with a wide range of colors. Chrome-tanned leather is commonly used in the production of footwear, bags, and upholstery. 8. Finishing: After tanning, the leather may undergo additional processing known as finishing. This includes dyeing, brushing, embossing, or coating the leather to enhance its appearance, color, and texture. Finishing techniques help create a variety of finishes, from smooth and glossy to textured or matte, depending on the desired final product. Conclusion: Leather raw materials are derived from various animal hides and skins, each with its unique characteristics and suitability for different applications. The leather production process involves careful sourcing, processing, and tanning of the raw materials to achieve high-quality, durable, and aesthetically pleasing leather products. Understanding the types of leather raw materials, their sources, and the various processing methods employed is crucial for businesses operating in the leather industry. By utilizing sustainable sourcing practices and adopting efficient processing techniques, businesses can produce environmentally-friendly and ethically sourced leather goods that meet the demands of consumers worldwide.

Your comment submitted.